The following guidelines should be considered when wiring ignition systems:

·Unsuppressed H.T. leads act as aerials and radiate very powerful interference signals. ALL applications must use suppressed HT leads, preferably resistance type rather than spiral wound or inductive. Typically these vary from 1000 ohms to 5000 ohms depending on lead length. NEVER use plain wire leads.

·It is recommended that applications also employ a suppressor capacitor (0.5 - 3uF) connected directly between the ignition coil(s) POSITIVE terminal and ground. Most points condensers are suitable. Multiple coils can share a single suppressor. ‘V’ and boxer engines with multiple coils should have a suppressor on each bank.

·Isolate the ignition system as much as possible from other sensitive devices, especially the ECU. Do not run non-ignition related wiring close to igniters, coils or HT leads wherever possible. Maintain maximum distance from radio transmitters and coaxial cables etc.

·Always use resistor spark plugs. These can be checked by measuring the resistance between the top of the spark plug and the centre electrode. On a resistor plug the resistance will be several thousand ohms.

·If insufficient ignition energy is causing a high-power misfire (especially on turbo/super charged engines), it may be necessary to reduce the spark plug gap. Gaps as small as 0.5mm (.020') may be necessary. This also reduces the amount of radiated electrical noise due to the lower firing voltage.

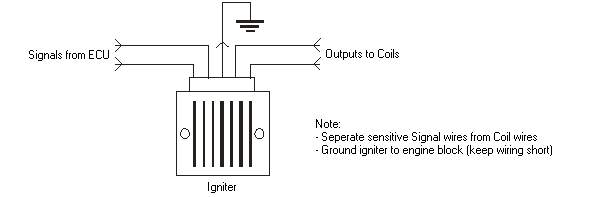

·Keep the input wiring to the igniter (from the ECU) separate from the output wiring of the igniter (to the coils) as shown below.

Separation of igniter input and output wiring