Digital inputs may be connected to switches, controllers or sensors to control various functions including launch control (clutch switch), anti-lag, high/low boost, water spray, dual fuel/ignition maps, nitrous oxide, air conditioning request and variable valve timing. Refer to here for frequency and on/off voltage specs.

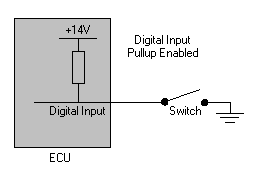

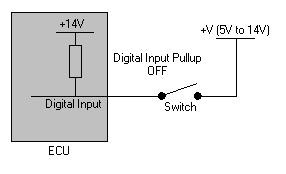

The diagrams below show the two methods of wiring Digital Inputs to a switch. When wiring other devices such as controllers it will be necessary to determine if these devices are active low or active high. If a switch or controller drives low then the Digital Inputs 'Pull-up Resister' will need to be enabled in PCLink Tuning Software.

Wiring of a Drive Low Switch to a Digital Input

Wiring of a Drive High Switch to a Digital Input

Vehicle Speed may be calculated using the output from a digital speedometer drive or in some cases from the speedometer assembly itself. This may be connected directly to a Digital Input. Some sensors will require that the Digital Inputs 'Pull-up Resister' is enabled in PCLink Tuning Software.

Continuously Variable Valve Timing (CVVT, VVT, VVTi, AVCS) Cam Position digital inputs can only be connected to Digital Inputs 1 to 4.

Reluctor or Optical/Hall sensors can be used to measure camshaft position on engines equipped with VVT systems. VVT position sensors should be wired to digital Inputs in the same manner as Trigger Sensors. This includes the use of Sensor ground and shielded cables. Shielded cable for Digital Input wiring is not included in the standard loom but can be purchased from your Link dealer. Not using shielded cable can result in cam shaft position measurement errors.

For engine specific information on the wiring of triggers and VVT position sensors refer to your Link dealer or linkecu.com.

Although not absolutely necessary, it is recommended to ease configuration that cam position signals are wired to the same number Digital Input channel as the corresponding solenoid control Auxiliary Output (refer following table). For compatibility, the following use of Digital Inputs and Auxiliary outputs is recommended for VVT wiring. Note that in practice any Digital Input/Auxiliary Output combination can be used.

Cam Shaft |

Digital Input |

Auxiliary Output |

Bank 1 Inlet |

DI 1 |

Aux 1 |

Bank 2 Inlet |

DI 2 |

Aux 2 |

Bank 1 Exhaust |

DI 3 |

Aux 3 |

Bank 2 Exhaust |

DI 4 |

Aux 4 |

In cases where the same camshaft position signal is used to measure camshaft timing as well as provide sync (firing order position) information, this sensor will usually be wired to Trigger 2.