Link ECUs have a large number of settings for calculating the required fuel delivery, these allow the tuner the flexibility to configure the fuel calculation to suit the particular application and the information they have available. The available settings depend on the selected Fuel Equation Mode. The chart on the Fuel Setup page provides information on the settings that are used in each Fuel Equation Mode.

Link ECUs offer these fuel equation modes:

·Traditional - Link ECUs have always used a fuel equation modelled around the major factors required to accurately control fuelling. This is a simplified equation who's primary fuel adjustment is a master fuel number to set overall fueling.

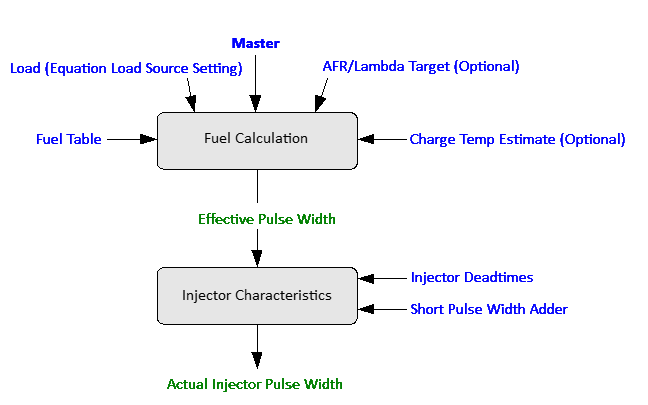

This simplified diagram illustrates how Link ECUs fuel calculation has traditionally worked.

·Modelled - This fuel equation takes into consideration all of the essential physical engine and fuel properties required to calculate the engines air charge and fuel volume.

The Traditional fuel calculation rolled together a lot of the constants like engine capacity, and injector flow into the Master Fuel setting. This was (and still is in a lot of cases) perfectly adequate for achieving an excellent tuning result. However with advancements in information available to tuners and the increasing use of alternative fuels, a more technically correct fuel equation improves the tuners ability to achieve an accurate tune. It also allows easier future changes.

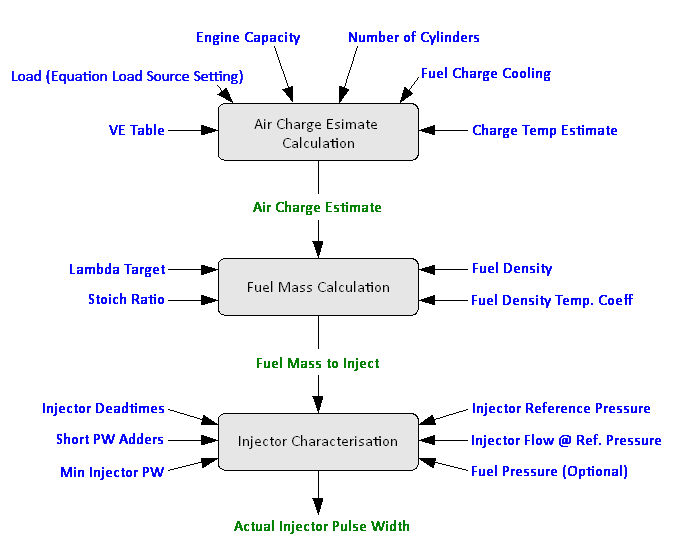

The Modelled fuel calculation mode provides metric settings for all inputs to the fuel equation as well as improved injector flow characterisation. The following simplified diagram shows how the Modelled fuel calculation works.

·Modelled - Multi Fuel - This extends the Modelled Fuel Equation to allow for the use of two different fuels. It is common now to run alternate fuels, particularly alcohol based fuels. Often it is a requirement to run two different fuels in the same vehicle (eg for road and race). With the availability of ethanol content sensors it is also common to use a variable blend of fuels.

The Modelled - Multi Fuel fuel calculation mode allows for tuning of the same engine on two fuels, then have a configurable means of blending between these fuels. The system can work from simple applications such as switching between fuels (eg 91 to 98 octane or gasoline to ethanol) right through to a full Flex Fuel application using a continuous measurement of ethanol content. There is more information on Multi Fuel here.

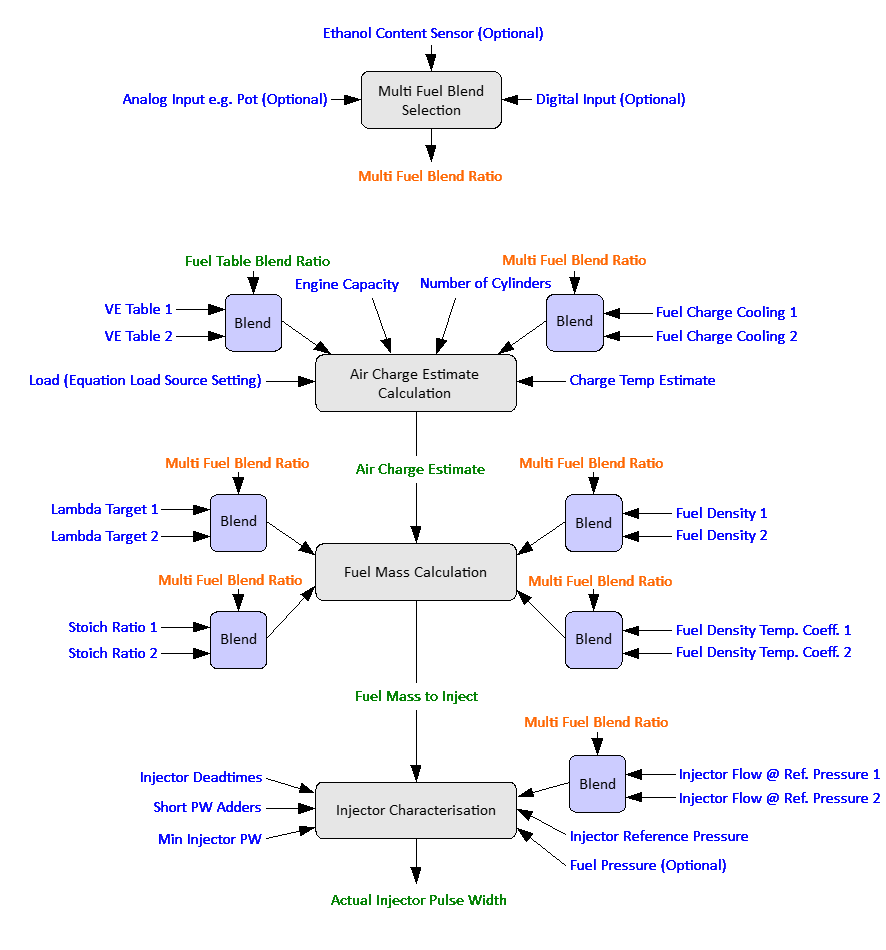

The following simplified diagram outlines the Modelled - Multi Fuel calculation.

While the Multi Fuel diagram appears complicated, the Multi Fuel system has been designed in such a way that simplifies setup and tuning. The tuner can simply start in Modelled fuel calculation mode, completely tune on one fuel, then when ready turn Multi Fuel on.

Selecting a Fuel Equation Mode

Selecting a Fuel Equation Mode is an important step in fuel tuning. Use of the more complex equation modes requires entering of exactly correct engine, injector and fuel information. There are also some correct tuning order steps that must be performed. However, a correctly setup modelled fuel equation provides good flexibility to future changes and better adaption to varying engine conditions.

Information required for accurate prediction of engine air charge and fuel delivery is:

·Injector Information - Accurate injector characteristics are probably the most critical factor in correct operation of the fuel equation. Often exact injector characteristic data is not available. Things you should know about the injectors:

·Injector flow varies significantly with differential fuel pressure. The differential fuel pressure across the injectors must be known in order to know how much fuel they will flow. Also if the differential pressure changes during injector operation then this must also be known.

·Injector flow changes with fuel composition. An injector will have different flow on different fuels. The density and viscosity of the fuel affect injector flow. Accurate information of the fuel used is essential. While most gasoline fuels have similar properties, the change of injector characteristics between gasoline and alcohol fuels can be significant.

·Injectors are not linear. An injector does not deliver twice as much fuel if you double the pulse width applied! The most significant factor in this non linearity is the dead time. Dead time varies with differential fuel pressure, applied voltage, and injector drive type (peak and hold or saturated). For a particular voltage and fuel pressure dead time is considered to be constant. However, at low pulse widths, dead time can vary significantly leading to very non linear injector behavior. Some injector suppliers can provide all the information on an injectors characteristics even over the non linear area. Knowing an injectors non linear behavior is essential when using large injectors at low pulse widths. Assuming an injectors dead times, or just using some default values will lead to poor fuel calculation.

·Modelled fuel calculation mode calculates the fuel on a per cylinder basis so the injector pulse width calculation assumes one injector (or two for staged injection) injector per cylinder.

·Fuel Information - In order for the ECU to determine the required mass of fuel to inject it must know the properties of the fuel being injected. Significant properties of the fuel are its stoichiometric ratio, density, how its density changes with temperature, fuel temperature and how much energy the fuel absorbs when it evaporates.

·Engine Air Dynamics - The static cylinder capacity of the engine and the dynamic volumetric efficiency are essential for calculating the mass of air inducted into the cylinder. Fortunately the volumetric efficiency can be found by tuning. Charge temperature estimation is also a very important factor in estimating air charge.

Here are some recommendations on selecting a fuel equation mode:

·All fuel equation modes allow injector dead time and non linear characterisation information to be used.

·If you are trying to tune on two fuels like a Gasoline/Ethanol blending situation or a switched fuel setup then use the Modelled - Multi Fuel Fuel Equation Mode. You WILL need accurate injector and fuel information for both fuel types. There is more information on Multi Fuel here.

·If you have accurate and NOT GUESSED or ASSUMED information about the injectors, fuel and engine then use the Modelled Fuel Equation Mode.

·If you want to use an existing tune or base map without re-tuning then use Traditional Fuel Equation Mode.

·Traditional Fuel Equation Mode is the fastest and easiest to setup and tune and can still achieve extremely good fuel control.

NOTE: A recommended fuel tuning procedure is described HERE.