Once the correct Trigger Mode has been selected and Triggers 1 and 2 configured, the trigger timing must be calibrated by checking the ignition timing using a timing light. Doing this tells the ECU where the trigger signals occur in relation to engine position.

Refer here for special instructions for ROTARY TRIGGER CALIBRATION.

To Calibrate Triggers

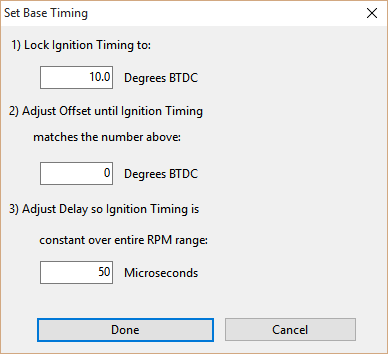

1.In the Triggers >Calibrate menu, click the Set Base Timing button  . This will open the Set Base Timing window.

. This will open the Set Base Timing window.

2.While the Set Base Timing window is open, ignition timing is locked to a constant value (The value entered in the "Lock Ignition Timing to" field).

3.Enter the ignition timing value that you want to see with the timing light in the "Lock Ignition Timing To" value. This value will depend on the location of available timing marks. 0 (TDC) and 10 deg BTDC are the most common values. Remembering to press enter after changing the value and the cell will turn blue to indicate the value has changed from what it was previously set to.

Trigger Calibration for all other Trigger Modes

Adjust the Trigger Offset number (middle field) until the timing seen on the timing light matches the "Lock Ignition Timing to" number.

4.To setup the Ignition Delay perform the following steps:

a)Set Ignition delay to 0.

b)Using a good quality timing light, increase RPM and observe ignition retard.

c)Increase Ignition Delay and repeat step b) and c) until the retard is eliminated.

d)A typical value is between 40 to 80 microseconds.

5.Click Done to keep the new Trigger Calibration settings. Otherwise click Cancel to restore the previous values.

6.Perform a STORE to permanently store the new trigger calibration setting to the ECU.

Trigger Offset is used to calibrate crank angle sensor position so that the ECU can calculate the correct engine position at any time.

Although the trigger offset affects both fuel and ignition, it is easiest to calibrate the trigger offset by getting the ECU to try and deliver the ignition timing at a fixed angle (e.g 10deg BTDC) and checking that the ignition is actually occurring at this point using a timing light. This procedure is described under Trigger Calibration.

Adjustment: ·Increasing this number will advance ignition and injection timing. ·Decreasing this number will retard ignition and injection timing.

Note: Refer to Trigger Calibration for information on calibrating trigger signals (setting the base timing).

Multi Tooth/Missing Trigger Mode

In Multi Tooth / Missing trigger mode the required trigger offset can be determined by measuring the angle between the tooth after the gap and sensor when the engine is at TDC number 1. ·If the gap passes the sensor before TDC1 in normal engine rotation direction then the offset number will be negative. ·If the gap passes the sensor after TDC 1 in normal rotation direction then the offset number will be positive. ·Example: If the tooth after the gap has gone past the sensor by 40 degrees when at TDC 1, then the offset number would be -40. ·Example: If the tooth after the gap is 60 degrees before the sensor when at TDC 1 then the offset number would be 60. ·NOTE: This trigger offset number could still be out by 360 degrees depending on the location of the sync pulse. If the number obtained results in the spark being fired when the valves are open, add or subtract 360. Eg -40 becomes 320. Eg 60 becomes -300. ·ALWAYS check the trigger offset with a timing light as described in Trigger Calibration. |

The normal procedure used to set Trigger Calibration does not work so well on Rotary engines. A piston engine will run happily with ignition timing set to fire on TDC. This is not so for Rotary engines.

Note: Most Rotary engines have a timing mark on their front pulley at 20 degrees ATDC. It is the tuners responsibility to confirm that the engine has a mark at 20 degrees. If the mark is at some other position, that position should be substituted in the following procedure. Late 13B engines only have a 20 degrees ATDC mark. Early 13B engines have a 5 and 20 degrees ATDC mark. 12A Engines have a 0 and 20 degrees ATDC marks.

Note: G4+ and G4X allocate the leading and trailing ignition drives slightly differently and so always check both the leading and trailing positions to determine the correct offset. You will also need to recheck the trigger offset when changing from leading waste to leading direct.

Rotary Trigger Calibration Procedure The idea of this trigger calibration setup method is to end up with the leading spark firing at 5 degrees ATDC and the trailing spark firing at 20 degrees ATDC. 1.Disable the fuel injectors by selecting OFF as the Injection Mode under the Fuel heading.This will ensure that the engine will not attempt to start while the ignition timing is being calibrated. 2.Enter a value of -20 degrees in the Trailing Split Table in all the cells around the area where the engine will run during trigger calibration. It may be necessary to set the entire table to the same value. 3.In the Triggers->Calibrate menu, click Set Base Timing. The Set Base Timing window will open. 4.Enter 0 as the Lock Ignition Timing To value to be used (remember to push enter after changing the number). 5.Attach a timing light to fire off the TRAILING spark of the front rotor. 6.Crank the engine while watching for consistent ignition operation at a fixed crank position. Adjust the Offset until the ignition is firing exactly on the 20 degrees ATDC timing mark. 7.Select Done to close the Set Base Timing window. 8.Enable the fuel injectors by selecting the relevant Injection Mode. 9.Perform a STORE so that the Trigger Offset value is permanently retained. Remember that the Trailing Split table has been modified so be careful not to Store changes to that by accident. 10.Repeat the above procedure once the engine is running (ideally at about 2000 RPM) as it is hard to get accurate timing readings during cranking. To do this, repeat the above procedure without setting Injection Mode to OFF. |